At a glance

Whether they are increasing energy efficiency or looking to showcase their skills in an international engineering competition, mechanical engineering technology (MET) students have been working hard during the spring semester on some amazing projects.

Whether they are increasing energy efficiency or looking to showcase their skills in an international engineering competition, mechanical engineering technology (MET) students have been working hard during the spring semester on some amazing projects.

Whether they are increasing energy efficiency or looking to showcase their skills in an international engineering competition, mechanical engineering technology (MET) students have been working hard during the spring semester on some amazing projects.

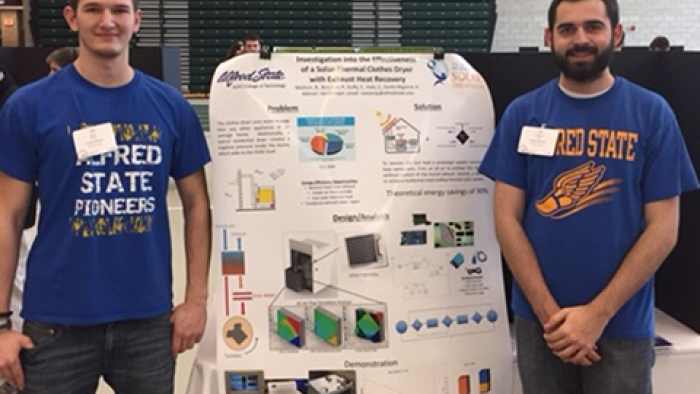

In one such venture, students have developed a solar-thermal clothing dryer prototype that uses 90 percent less energy than a traditional dryer and improves drying performance. Jon Owejan, assistant professor of Mechanical and Electrical Engineering Technology, said the dryer has a novel energy-recovery system and a solar-thermal heat source.

In one such venture, students have developed a solar-thermal clothing dryer prototype that uses 90 percent less energy than a traditional dryer and improves drying performance. Jon Owejan, assistant professor of Mechanical and Electrical Engineering Technology, said the dryer has a novel energy-recovery system and a solar-thermal heat source.

In order to create the prototype, the students designed two heat exchangers, fabricated parts, and retrofitted an existing dryer.

“These students are taking a real hard look at something that’s in every household and making it a lot more efficient,” said Matthew Lawrence, associate professor of Mechanical and Electrical Engineering Technology.

Peter Borglum, of Pittsford, said he is proud to have been involved in this project, which he said shows “such promise” and considerable cost-effectiveness.

“Hopefully the results of our work will spur future MET projects that put the knowledge we have gained into practice,” Borglum said.

In another project, through a collaboration with the Propane Education and Research Council (PERC) and Yanmar Energy Systems, Alfred State has commissioned a micro combined heat and power (Micro CHP) cogeneration system that utilizes a natural gas engine to produce 5 kilowatts of power. As part of his senior project, Luke Miller, of Hornell is helping to install the system, which will become a regular part of the MET teaching curriculum.

In another project, through a collaboration with the Propane Education and Research Council (PERC) and Yanmar Energy Systems, Alfred State has commissioned a micro combined heat and power (Micro CHP) cogeneration system that utilizes a natural gas engine to produce 5 kilowatts of power. As part of his senior project, Luke Miller, of Hornell is helping to install the system, which will become a regular part of the MET teaching curriculum.

According to Owejan, the cogeneration system has a higher efficiency than traditional stand-by generators because it captures the waste heat and re-deploys it for a number of uses, such as domestic hot water, heating pools, radiant heating systems, and more.

“This is a great example of next-generation energy systems the students are being exposed to in the MET program,” he said.

Michael Alfano, sales application engineer at Yanmar, said, “We at Yanmar are pleased to have the opportunity to work in partnership with the students, faculty, and staff of Alfred State on the Yanmar Micro Cogeneration Project. We are excited to introduce micro cogeneration concepts and ideas and assist in facilitating an operational system for the students to observe and learn from.”

MET students have also, for the second consecutive year, designed and fabricated an off-road vehicle for a Baja SAE intercollegiate engineering competition taking place May 7-10 at the University of Maryland, Baltimore County. The object of the competition, according to bajasaemaryland.umbc.edu, is to provide SAE student members with a challenging project that involves the design, planning, and manufacturing tasks found when introducing a new product to the consumer industrial market.

This year, the Alfred State vehicle features on-board instrumentation and an advanced suspension. About 15 students will be making the trip to Maryland to compete against approximately 100 other colleges.

This year, the Alfred State vehicle features on-board instrumentation and an advanced suspension. About 15 students will be making the trip to Maryland to compete against approximately 100 other colleges.

Nathan DeMario, of South Wales, said working on the Baja team has had a significant impact on him.

“It has changed my view of my college experience, it has helped me develop a relationship between information gained in class work and applying the information that we have learned, and it has also allowed me to enjoy my college experience more than I ever thought I would,” he said.

Nathan Sheckler, of Phelps, said this year’s Baja vehicle has “made leaps and bounds over last year’s” entry.

“It’s really exciting to see each individual part come together to make something this cool,” Sheckler said. “It will be an amazing opportunity to compete with this car in Maryland, put it through such a rigorous test, and truly see how well it is built.”

Solar-thermal dryer photo: Mechanical engineering technology (MET) students Brian Mothon, of Galway left, and Zach Hale, of Rochester, stand in front of a poster that explains their solar-thermal clothes dryer project. MET students who were also involved but are not pictured are Peter Borglum, of Pittsford; Kyle Smith-Miglorie, of Avon; and Evan Duffy, of Hamburg.

Cogeneration system photo: Shown here are Yanmar engineers Yoshinori Jodo, left, and Michael Alfano inspecting the installation of the micro combined heat and power (Micro CHP) system.

Baja team 2015 photo: Pictured are mechanical engineering technology students and their entry for the Baja SAE international engineering competition taking place May 7-10 at the University of Maryland, Baltimore County. From left to right, are Jason Walker, of Phelps; Zach Shadbolt, of Attica; Alex Fisher, of Painted Post; Nathan Sheckler, of Phelps; Nathan DeMario, of South Wales, and (kneeling) Eli Bell, of Shinglehouse, PA.